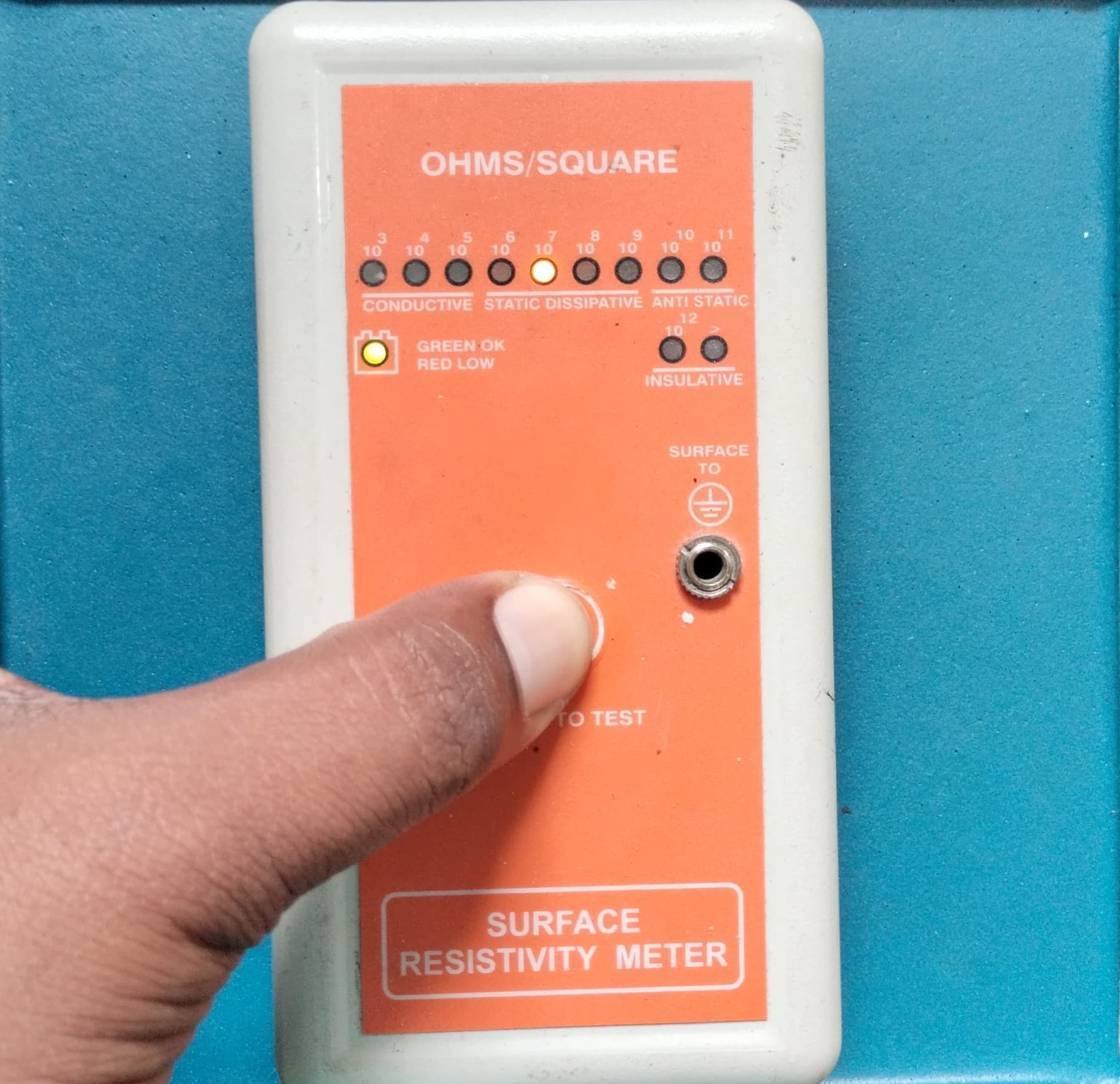

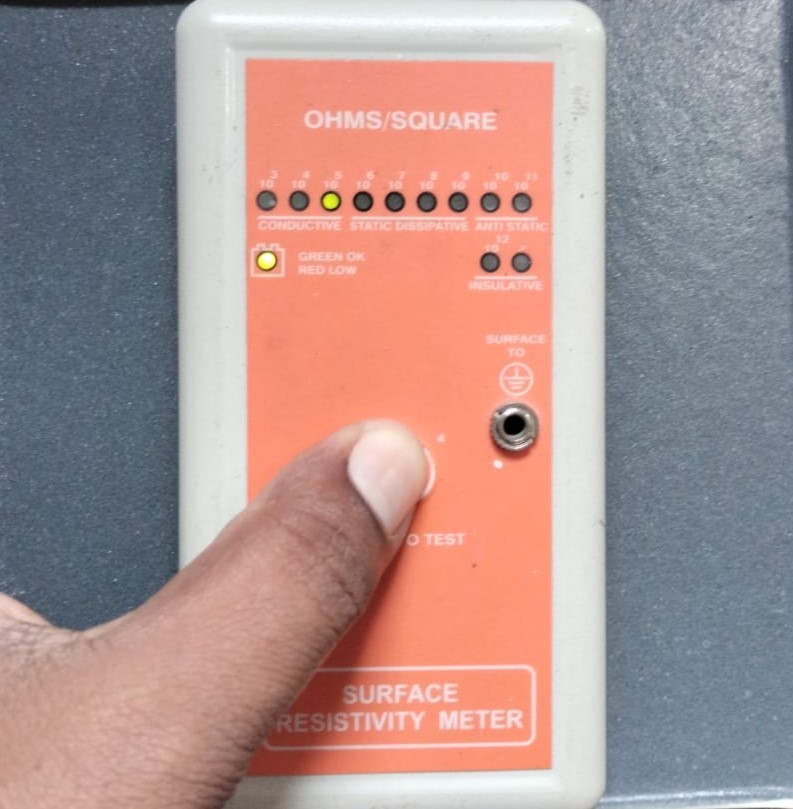

Neostatic HDT is a seamless, joint less uniquely formulated, self-levelling, water-based PU concrete flooring system with special carbon nano-tubes to provide electrostatic properties. This is a cutting-edge technology wherein, exceptional chemical, abrasion & impact resistance are obtained, combined with ESD properties. Capable of providing consistent resistance values viz. 106 to 109 ohms, or 104 to 106 ohms, Neostatic HDT is available in both dissipative and conductive versions. It can be applied upto 5mm and is ideally suited to provide mechanical as well as electrostatic properties.

- Ideally suitable for Electronic warehouses and assembly areas, solvent storage and filling areas, Hospitals and operation theatres, very high abrasion areas such as assembly lines, loading and unloading areas where ESD properties are desired, ordnance factories, ammunition depots and store-houses handling combustible gases

Features & benefits include:

Highly consistent readings of dissipative as well as conductive range, joint less, monolithic flooring and easily cleanable, excellent bond to concrete, higher impact resistant and can withstand lower temperature and unlike epoxy, Neostatic ESD is fast-setting thus resulting in faster turn-around, very good abrasion, impact and scratch resistance.

Neostatic HDT-Dissipative

Neostatic HDT-Conductive